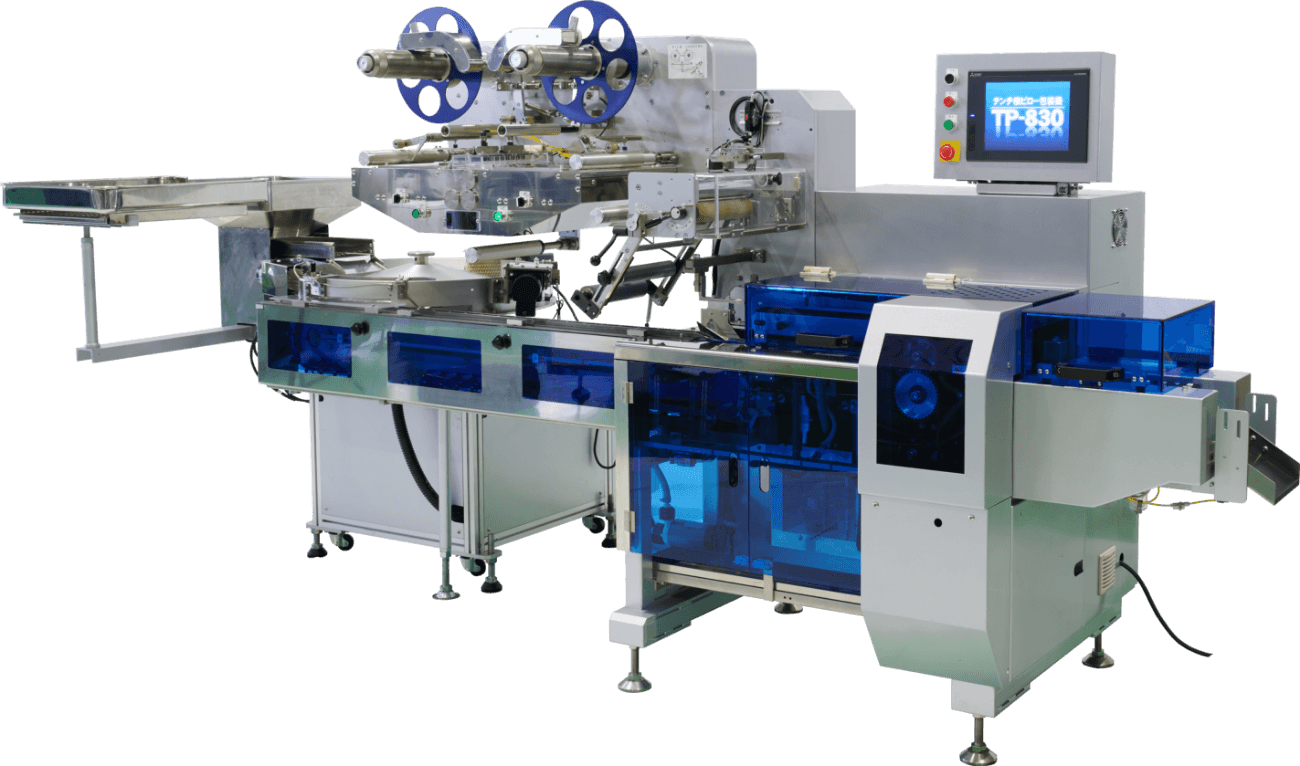

CARTONING MACHINE MODEL TC-320 (for Sheet Chewing Gum)

Main Specifications

- Capacity

- Maximum 100 carton/minute (varies depending on products and specifications)

- Option

- Printer, print checker, and hot melt

- Application

- Sheet chewing gum

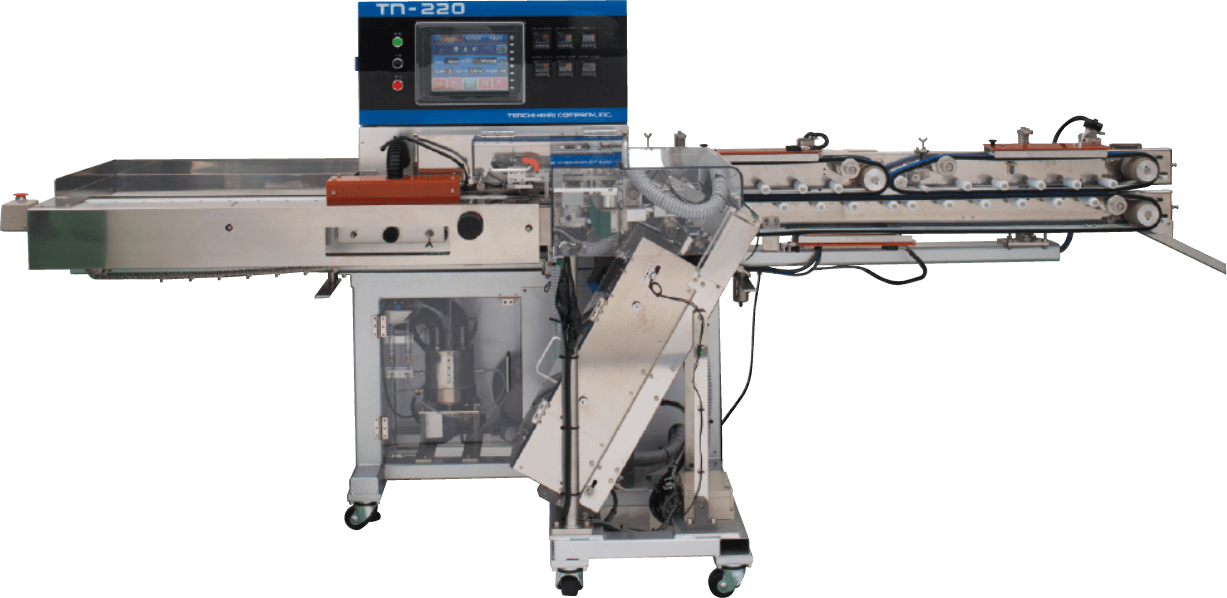

CARTONING MACHINE MODEL TC-330 (for Powder Sticks)

Main Specifications

- Capacity

- Maximum 35 carton/minute (varies depending on products and specifications)

- Option

- Printer and print checker

- Application

- Stick pillow products, three-way seal products

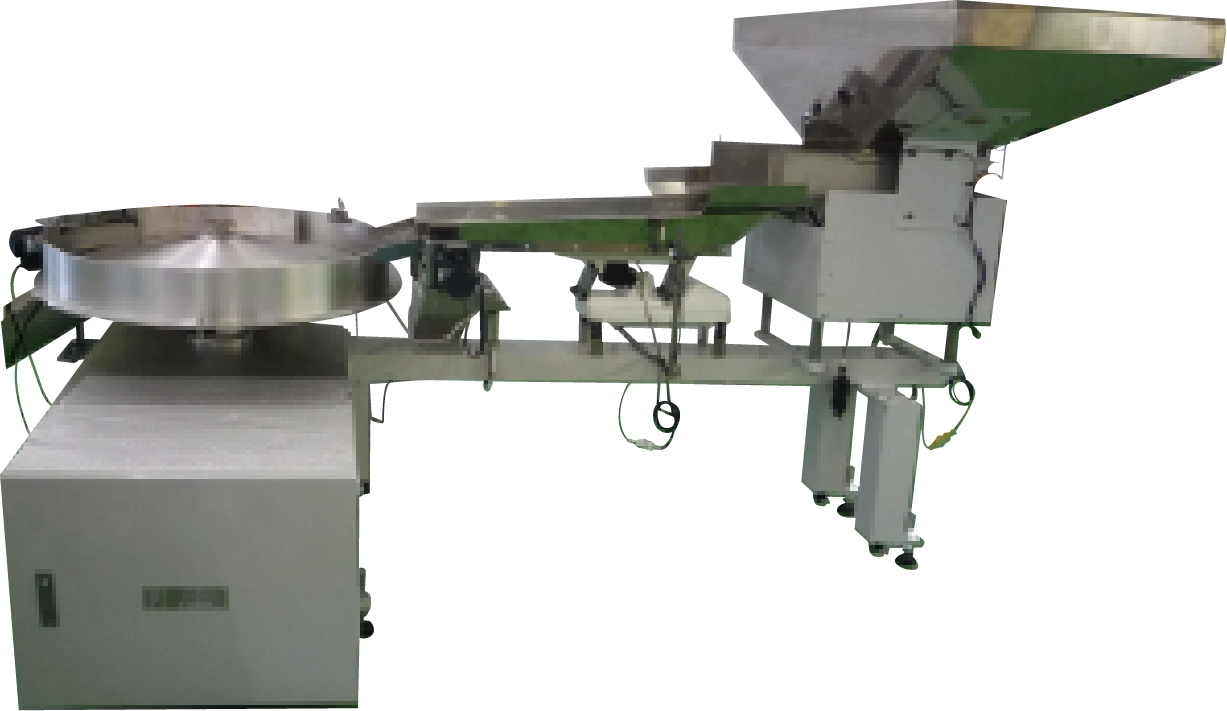

CARTONING MACHINE MODEL TC-600

Main Specifications

- Capacity

- 30〜40 boxes/minute

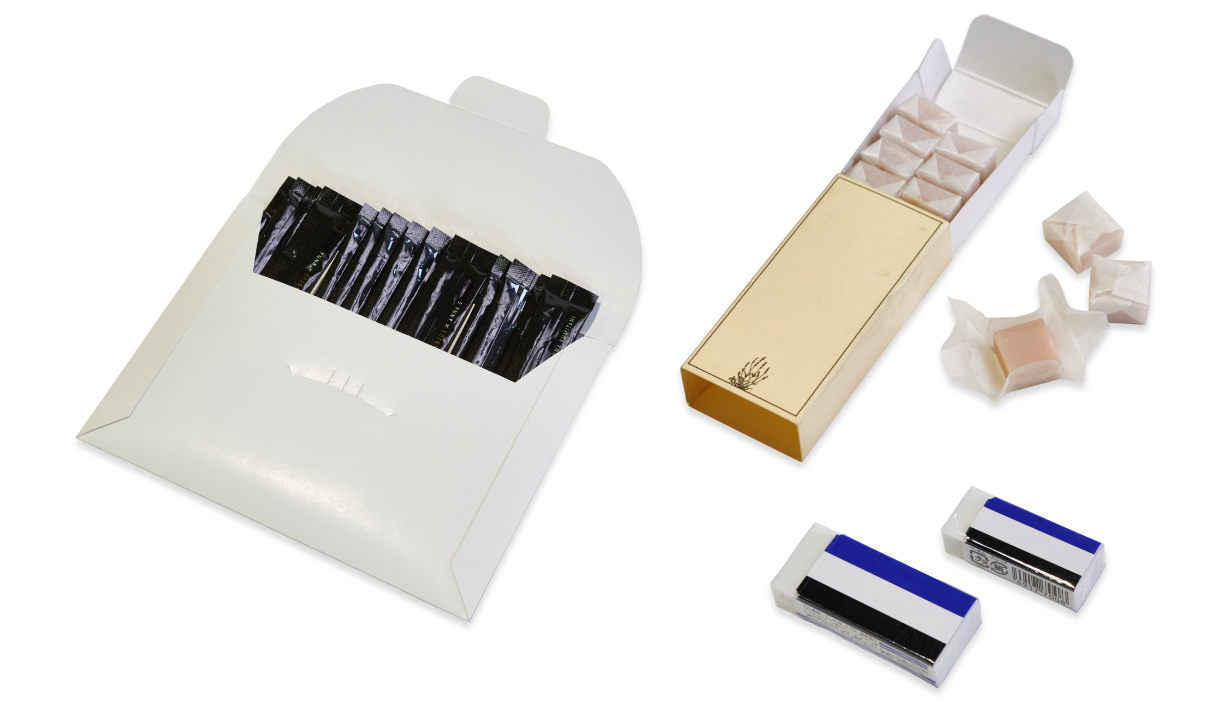

- Application

- Chocolate, candies, gum, etc.